Precision Machined Components & Bespoke Fasteners

Made to your designs or reverse engineered

Creating Your Unique Components

Why Choose Wulfrun?

We’ve been doing this for a long time – over 35 years!

This means that we’ve seen it all; there’s no component you might throw at us that we can’t fabricate, either from your existing designs or parts.

We can create:

- Working parts as per your drawings

- Exact components reverse engineered from existing parts

- Detailed part drawings

- A fully consultative process

Material Grades

Our precision machined components are made to order and can be created out of any available material grade.

Wulfrun can provide components for the following stainless steel material grades: 304 / 304L, 310, 316 / 316L, 321, 347, 410, 421, 422, 431, 904L, ISO 3506-1 / 2 – A4 (50 / 70 / 80 / 100), ISO 3506-1 / 2 – A2 (50 / 70 / 80 / 100).

Wulfrun can provide components for the following carbon & alloy steel material grades: EN3A (070M20), EN8 (080M20), EN8D (080A42), EN16 (605M36), EN19 (708M40), EN24 (817M40), EN26 (826M40), ISO 898-1 Grade 8.8, ISO 898-1 Grade 10.9, ISO 898-1 Grade 12.9, ISO 898-2 Grade 8, ISO 898-2 Grade 10, ISO 898-2 Grade 12, C35E, C45E, 25CRMO4, 42CRMO4.

Wulfrun can provide components for the following petrochemical material grades: ASTM A193 B6, ASTM A193 B7, ASTM A193 B7M, ASTM A193 B8 (CLASS 1 & CLASS 2), ASTM A193 B8T (CLASS 1 & CLASS 2), ASTM A193 B8C (CLASS 1 & CLASS 2), ASTM A193 B8R, ASTM A193 B16, ASTM A320 L7, ASTM A320 L7M, ASTM A320 L43, ASTM A194 2H, ASTM A194 2HM, ASTM A194 7, ASTM A194 7M, ASTM A194 8, ASTM A194 8A, ASTM A194 8M, ASTM A194 8MA, ASTM A194 8T, ASTM A540 GRADE B21, ASTM A540 GRADE B22, ASTM A540 GRADE B23.

Wulfrun can provide components for the following power generation material grades: 1.4913 – X19CRMOVNBN11-1, 1.4923 – X22CRMOV12-1, 1.6582 – 34CRNIMO6, 1.7709 – 21CRMOV5-7, 1.7711 – B16, 1.7729 – DUREHETE 1055 – 20CRMOVTIB4-10.

Wulfrun can provide components for the following nickel alloy and duplex sheet material grades: INCONEL 600, INCONEL 625, INCONEL 718 – API 6A / AMS 5662 / AMS 5663, INCONEL 725, INCONEL X-750, ASTM A453 GRADE 660 (A/B/C/D), HASTELLOY C22, HASTELLOY C276, HASTELLOY X, S32760 ‘A’ / ‘S’ / FG / FLT / NORSOK D59 / NORSOK D60, S31803, S32750, S31254 / 254SMO, MONEL 400, MONEL K500, INCOLOY 800, INCOLOY 800HT, INCOLOY 825, INCOLOY 925, NIMONIC 80A, 17-4 PH, WASPALOY.

Wulfrun can provide components for the following non-ferrous material grades: HIDRURON 130, HIDRURON 191, COPPER NICKEL 70/30, COPPER 90/10, PB101, PB102, PB103, PB104, TITANIUM GRADE 2, TITANIUM GRADE 5, TITANIUM GRADE 7, DEF STAN 02-833, DEF STAN 02-834, C63000, C63200, CZ121 / CA104.

Wulfrun can provide components for the following aircraft material grades: JETHETE X-152.

About Our Bespoke Service

It can be frustrating trying to replace out-of-date fasteners, or to try to fabricate new, unique parts.

At Wulfrun, we love a challenge, that’s why we’ll take on any manufacturing job, big or small, and when we say bespoke, we mean it!

Even if you’re lacking dimensional standards or material grades, we’ll go the extra mile to provide you with the right component solution

Key Wulfrun Benefits

Consultative Service

We’ll work closely with you and your team to ensure that we get your new component absolutely perfect. Nothing less than perfection will do.

Rapid Turnarounds

We turn around bespoke components quickly, meaning that you’ll have your part in no time at all.

Work From Your Designs

We can work directly from your drawings, or we can create the drawings for you for future reference.

Make ANY Part!

When we say any part, we mean it! If you need a bespoke component making, we’re your end-to-end solution.

Our Step-By-Step Process

Consultation

Our process begins with a meeting between our experts and your team. This meeting is designed to help us understand your specific needs and requirements, allowing us to create the perfect bespoke fasteners and precision machined components, every time.

We will discuss the intended use and application of your new fasteners, as well as any specific performance or design criteria that must be met.

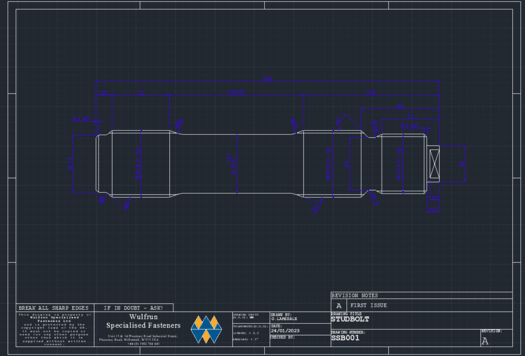

Design

Once your requirements have been established, we proceed to the design phase. This is where our technical team will create detailed drawings of your new fasteners and/or components, all based on your specifications or previous drawings for each part. We’ll also detail the appropriate materials and manufacturing processes that will be used.

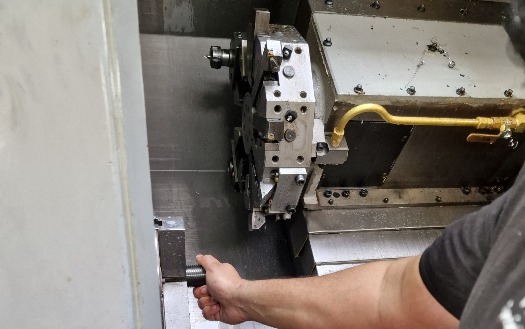

Manufacture

After your new designs are finalised, we move onto manufacturing your bespoke fasteners and components. We employ a variety of processes to guarantee the best results. This includes: milling, turning, thread rolling, screw cutting, broaching, spark eroding, grinding, laser cutting and forging.

Once machined, we finish with any necessary heat treatment or surface finishing.

Quality Assurance

Our rigorous quality assurance process ensures that all parts that leave our workshop meet the specified design and performance criteria.

This includes inspections, testing, 3.2 third party and careful measurements, checking that all fasteners and components are 100% up to standard and ready to be used.

Delivery

Once the fasteners and components have been manufactured and inspected, we package and deliver them directly to you. This involves transportation and logistics coordination to ensure that they are delivered on time and in pristine condition.

Quality Assurance

As most of our products are used in quality critical applications, it’s imperative that they are of the highest integrity – failure isn’t an option.

Wulfrun Specialised Fasteners and stud manufacturer operate a formal quality system accredited by LRQA to BS.EN.ISO 9001-2015 and are API20E BLS2 approved. In addition to this, we are able to integrate customer specific standards and quality system requirements to ensure that we meet any unique quality requirements.

The Wulfrun quality system lays down mandatory procedures and controls for all elements of our supply, from full traceability on material purchase, through to order completion. Quality is further reinforced by our on-site XRF spectrometry of all incoming material and finished products.

Our fully equipped inspection facility is complemented by our coordinate measuring machine, which allows us to perform intricate inspection operations, enabling us to produce detailed dimensional reports.

Our Accreditations

Free, No-Obligation Quote

Get in touch and let us know your requirements. A member of our specialist team will be in touch with a bespoke quote at the right price.

Prefer to call? Get in touch directly: